Why Descon360?

On the international project side, we offer project management and study management services. Furthermore, we specialize in project leadership services and can partner with an engineering team to deliver the full project execution team. For international projects, we typically work with tier 2 or more junior clients who require a study to be performed on an asset to obtain financing to build the project.

We serve all international type projects and studies and can provide bankable studies compliant with NI 43 101.

Our team has a wide range of expertise, from mining and minerals-based project to oil and gas, to hydro and energy projects. With a proven track record of managing projects across the world, our clients trust us to create and build effective solutions.

Our Portfolio

Location:

Toronto, ON

Scope:

Project Management and Coordination of Design and Construction

Description:

2004-2005: Project Management of Design build project; coordinated management with Comstock Canada Ltd and American Water Systems; provided technical support of SCADA/PLC architecture in automation of water filtration plants

Location:

Toronto, ON

Scope:

Project Management and Integration of Automation Systems

Description:

2005-2006: Project Manager for automation engineering scope including systems integration of instrumentation and control panels on a Delta V foundation-fieldbus communications architecture.

Location:

Toronto, ON

Scope:

Project Management and Integration of Automation (PLC and SCADA) Systems

Description:

2006: Project Manager responsible for City of Toronto wastewater project involving integration of instrumentation and GE PLC control in hazardous locations

Location:

Regina, Saskatchewan

Scope:

Project Management for Design and Construction Brownfield Refinery Project

Description:

2007-2010: Project management of CCRL’s refinery expansion and revamp was to process low sulphur synthetic crude produced from Athabasca bitumen. Provision of full engineering, project controls, information management, document control, procurement support, and construction management for the brownfield refinery upgrade. Revamp included upgrades/expansion to oil crude line, tank farm and processing facilities in the refinery.

Location:

Ankara, Turkey

Scope:

Project Management for Design and of Nickel Mining Project

Description:

2012-2013: Project Management of Gördes Nickel Project – a nickel laterite mining/minerals ore processing plant with a capacity of10,000 t/y of nickel, located in the province of Manisa, Turkey. Included the detailed engineering and partial procurement support related to Process Plant areas.

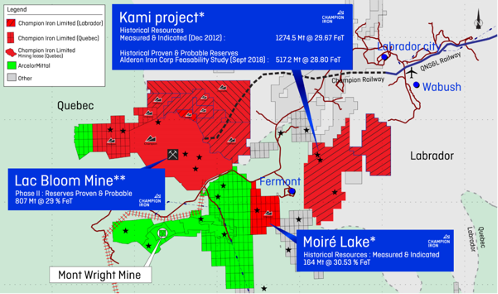

Location:

Labrador City, Canada

Scope:

Project Management for Design and Construction Open Pit Iron Ore Mining Project

Description:

2013-2015: Project Management of scope, costs and schedule in EPCM arrangement. Iron ore site in Labrador; scope included the open pit mine, the crushing, conveying and process plant (crushing/grinding), and rail load-out. Railway infrastructure, signalling and interfacing with QNS&L for the transport from Labrador City to the Port of Sept-Iles. Port facilities also included car dumper and stacker/ reclaimer for product export to sea at the Port. Mine capacity of 80 Mtpa. Railways, bridges and port work are amongst the challenges for engineering amidst very sensitive permitting and environmental regulations.

Location:

Ethiopia, Africa (Port of Djibouti)

Scope:

Project Management for Design of Solution Mining Potash Project

Description:

Project Managment responsible for project scope, costs and schedule. Basic Engineering completion of FEL 3 Level Study in a Lump Sum commercial arrangement. Solution Mining Operation in the Dallol Area of NE Ethiopia.

Scope included the brine solution mining, the solar evaporation ponds and the process plant facilities, for a mining operation of 1.4 Mt of MOP (Muriate of Potash) and 0.6 Mt of SOP (Sulfate of Potash).

Scope also included logistics, road access/rail transport to the Port of Djibouti for transport of final produce to marketplace.

Location:

Saskatoon, Saskatchewan, Canada

Scope:

Project Management for Design and Construction of Underground Mining Potash Project

Description:

2016-2020: The project team responsible for scope, cost and schedule for the above ground non-process infrastructure and utilities of the mine site. The detailed scope involved mass earthmoving, extensive infrastructure, high voltage power transmission /distribution and provision of utilities to the site.

It involved a 10 km2 complex tailings management area and an extensive rail spur load-out at the mine. The rail scope includes the Jansen property onsite rail, a joint access spur to the main Canadian Pacific (CP) and Canadian National (CN) mainlines. The +100 km of rail to the CN/CP mainlines will take mine product (pelletized potash) to a port location on the west coast.

Includes the delivery port acquisition/development with storage/unloading processes and mine site infrastructure/utilities. sensitive permitting and environmental regulations.

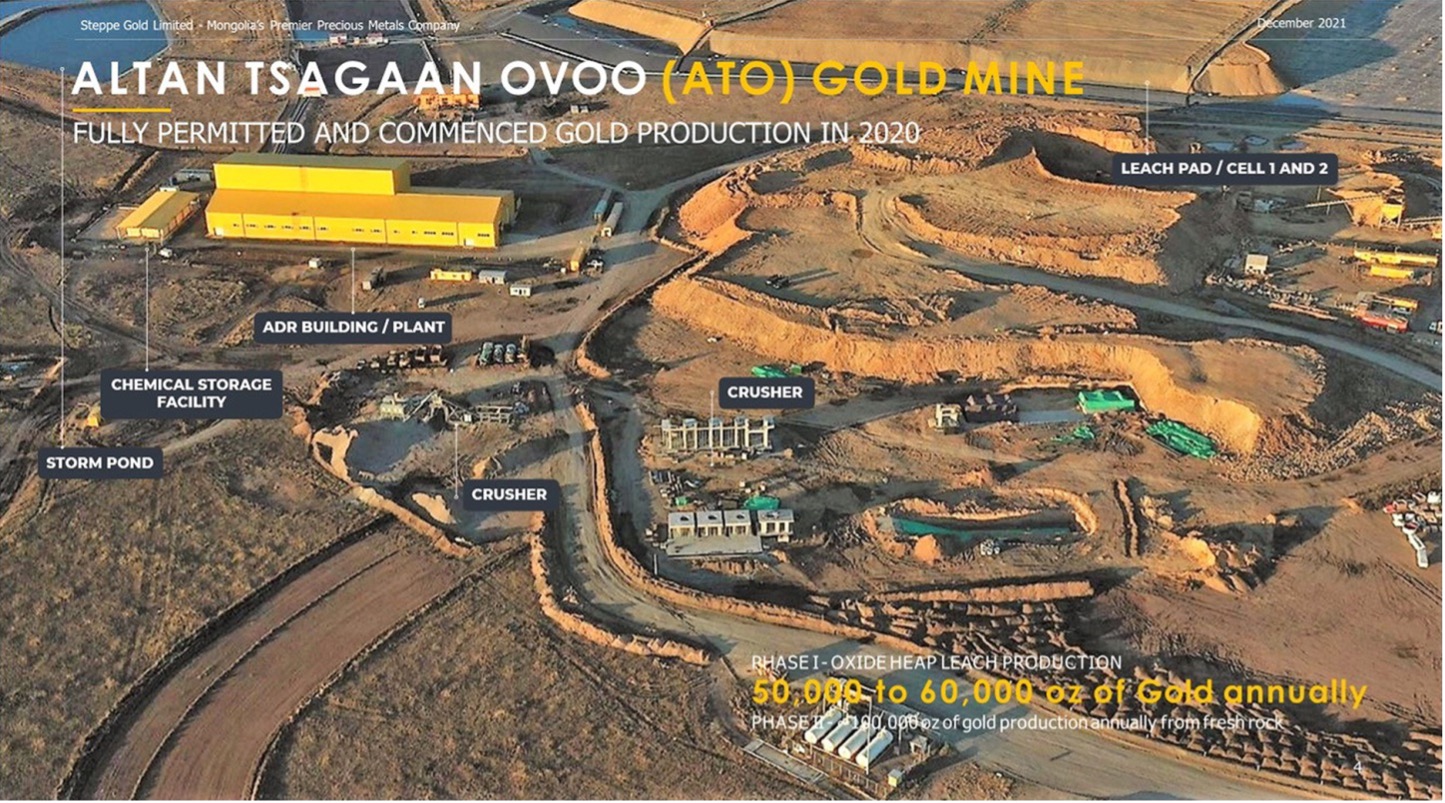

Location:

Mongolia, Asia

Scope:

Project Management for Design and Completion of Feasibility Study of Open Pit Mining Gold Project

Description:

2021: Study Manager: Management scope for a full feasibility study, compliant with NI 43-101, for Steppe Gold on the ATO Mungu Gold Silver Project, located in Mongolia. Brownfield Project (Operating Open Pit Mine).

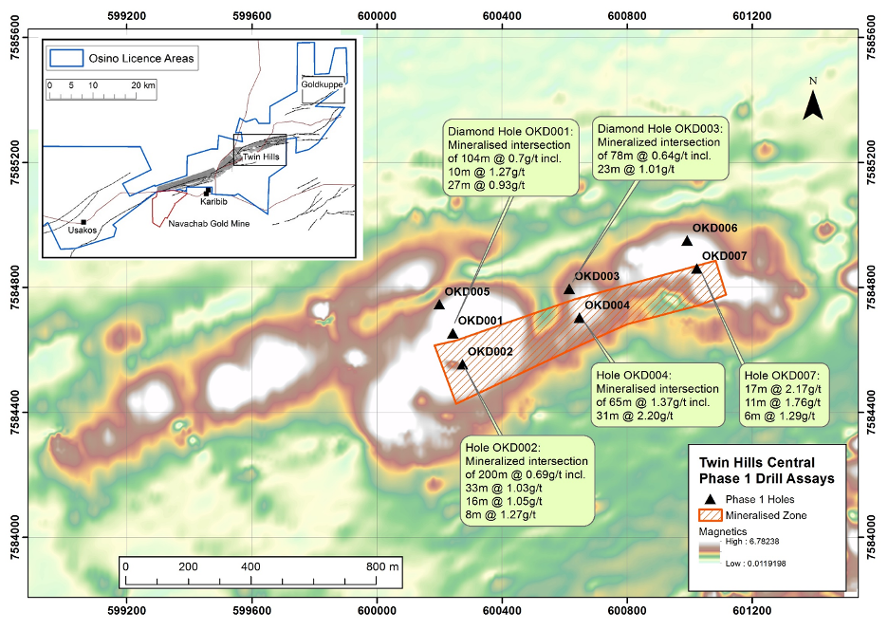

Location:

Namibia, Africa

Scope:

Project Management for Design and Completion of Feasibility Study of Open Pit Mining Gold Project

Description:

2021-2022: Study Manager: NI-43 101 compliant enhanced Feasibility Study for Twin exploration for 5.2 MTPa (200,000 oz Au per annum) Gold Plant, in Namibia, Africa. Processing Plant, Open Pit Mine and Infrastructure scope.

Location:

Burkino Faso, West Africa

Scope:

Project Management for Design and Completion of Feasibility Study of Open Pit Mining Gold Project

Description:

2021-2022: Study Manager: NI-43 101 compliant Feasibility Study 10 MTPa (oxide and sulphide) Gold Processing Plant, in Burkina Faso, Western Africa. Processing Plant, Open Pit Mine and associated infrastructure

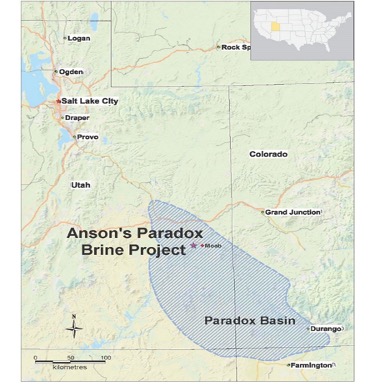

Location:

Moab, Utah, USA

Scope:

Project Management for Design and Completion of Definitive Feasibility Study of Direct Lithium Extraction Facility including Processing Plant and associated Infrastructure

Description:

2022: Study Manager: Anson Resources/A1 Lithium: Definitive Feasibility Study (DFS) compliant to JORC standards for Paradox Lithium Carbonate Processing Plant, in Moab, Utah, USA. Plant will produce 12,000 TPa of Lithium carbonate, with processing facility, infrastructure, load out and associated utilities.

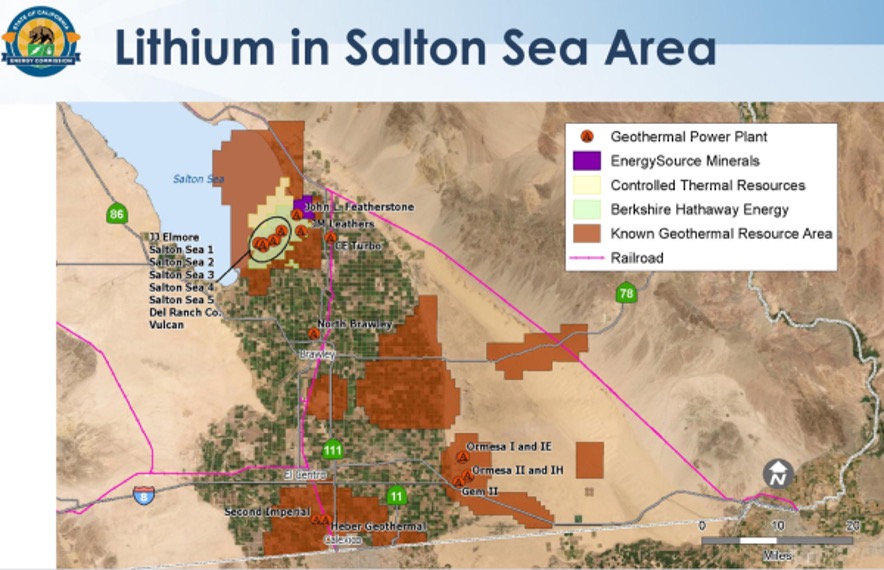

Location:

California, USA

Scope:

Project Management for Design and Completion of Feasibility Study of Lithium Hydroxide Facility including Processing Plant and associated Infrastructure

Description:

2022: Study Manager: BHER (Berkshire Hathaway Energy and Renewables) PFS for Lithium Hydroxide Plant, pilot plant scope (LRD Revamp) and pre-feasibility scope for 60,000 TPa producing plant in California, USA. Processing plant, infrastructure, associated utilities.

Contact Us

Would you like to start a project, or do you have a question for our team? Please fill out the form below and a member of our team will get in touch within 2-3 business days.